Cablex

Cablex group needed a single IT system to unify its operations in 8 companies across Europe and in Chine. They selected Microsoft Dynamics ERP, which they implemented with the help of BE-terna. The company provided quality real-time information to its management to support planning of all aspects of manufacturing, which helps the company stay more competitive in the market. The company also improved IT system reliability, cut costs and the efficiency of internal processes for transactions between group companies.

Situation

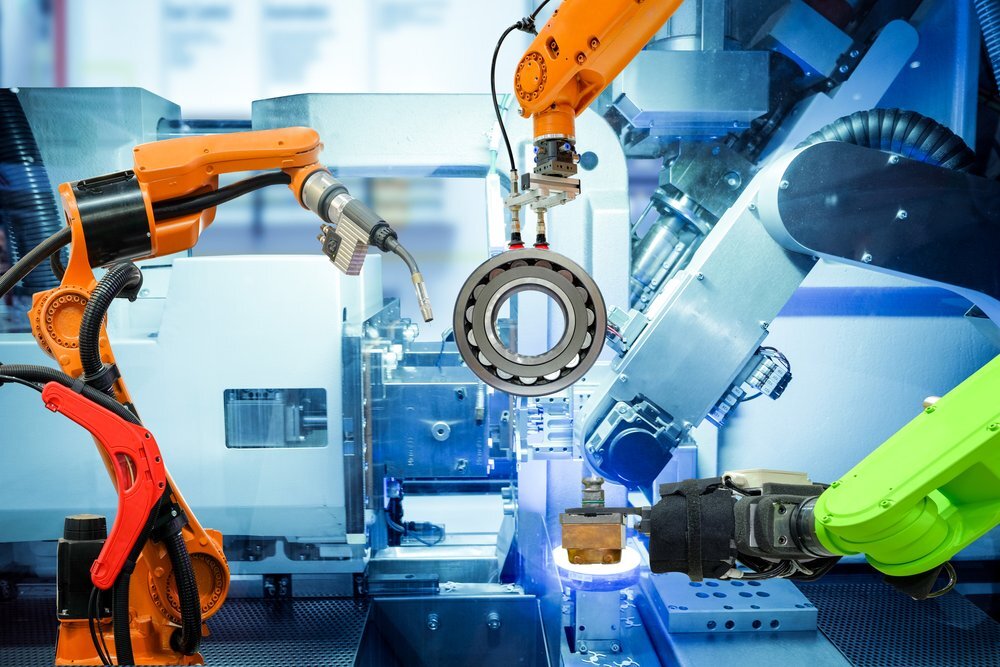

Cablex Group is a system developer and supplier of cable harnesses, silicone parts and mechanical assemblies. The company employs 1,800 people in 8 manufacturing units in Slovenia, Serbia, Poland, Turkey and China. The company's customers are leading manufacturers of home appliances, car industry companies and others.

In 2008, the company implemented Microsoft Dynamics AX 2009 to replace internally developed local solutions used in different countries as well as Microsoft Dynamics NAV, deployed in the company’s headquarters. With constant growth and expansion into new countries, the company management began considering migrating to a new version.

If we want to operate effectively and stay responsive, we need a single IT system and unified business principles. Our existing solution supported our business and commercial processes but we also needed accounting and payroll functionalities, as this was the only way to provide the management with the up-to-date information it needs to make their decisions.

said Mirko Hudovernik, CIO in Cablex.

Different companies used different technologies, making it impossible to acquire timely and quality information, which made IT system consolidation a top priority for the upgrade project.

The company reviewed and evaluated different ERP systems and decided to acquire Microsoft Dynamics and to work with partner BE-terna, which successfully implemented AX 2009 in 2008. An important factor was the international focus of Dynamics ERP, which is adapted to legislative requirements of different countries.

We've worked with Cablex in the past and we provided them with comprehensive support in all of the countries, where they needed the solution, which was also a challenge for us,

explained Iztok Juvan, Chief Technology Officer, BE-terna.

Solution

Cablex rolled out the solution in several stages. The solution was initially deployed in the company headquarters in Slovenia and was later rolled out in companies in Serbia, Poland, Turkey and China. To support it, the company implemented a high availability data center and a backup site which ensures business continuity even in the event of a failure of the primary location.

Company implemented a broad range of modules and functionalities - from manufacturing support and supply chain management to procurement, marketing, HR and finance modules. Cablex also implemented solutions for reporting and manufacturing micro-planning.

Of course, we rolled out some customization to reflect our needs. For example, the price of copper is an important factor for our operations and it is important that procurement can access price trends and statistical data to make better informed decisions about this important raw material.

explained Mirko Hudovernik, CIO in Cablex.

Benefits

By implementing a unified ERP system throughout the Cablex group, the company management has much more powerful planning tools at their disposal. Centralized planning helps the management to decide which country will fulfill individual orders. Their decisions are based on calculated costs of labor, transport, sales trends and other factors. The electronic ordering functionality is also supported in the solution.

Manufacturing planning is very important to us. We have over 3,000 products with more than 10,000 materials, which is extremely difficult to plan. To succeed with such a complex offering you need an effective system that provides detailed information you can analyze and use to support your decisions.

At the same time, the company can now monitor the performance of individual manufacturing units in individual countries, where Cablex is present. This is the result of rolling out a single solution for all companies that provide unified and accurate real-time information that helps the management access business information easily and quickly.

Lower cost is another important benefit. The implementation of a centralized IT system that subsidiaries access remotely through remote desktops, removed the cost of maintaining on-site server infrastructure in different countries.

The company also reduced cost by moving to electronic transactions between group companies that no longer require paper-based processes. Data transfers and all communication are now performed in electronic form. This also results in less manual work and errors to improve the effectiveness and productivity of employees, who can now focus on more important tasks.

By implementing a Microsoft Dynamics solution Cablex group provided its management and employees with the right information at the right time. The IT system covers their entire operations and provides IT support for the most important processes while it also presents the platform for future expansion and growth.

We’ve achieved important benefits in improving sales and driving more effective operations. We improved inventory and warehousing processes. The nature of our customers' business dictates that we need to ensure very accurate and effective warehousing operations.